Non-woven. Air Lay

We produce complete lines for non-woven manufacturing using the pneumatic system with randomised arrangement of fibres.

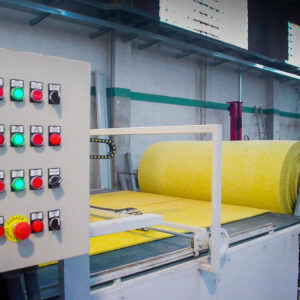

Engineered for High-Quality Felt Production

At MARGASA, we design and build complete non-woven manufacturing lines using the Airlay system, ideal for the production of thermobonded or needled felts. Our lines are designed for performance, flexibility, and integration, capable of producing fiber webs up to 3 meters wide, with weights ranging from 350 to 3,500 g/m².

- Web Widths: Up to 3,000 mm

- Web Weights: From 350 to 3,500 g/m²

- Production Rates: Over 3,000 kg/h depending on fiber and line setup

- Fiber Types: Synthetic, natural, recycled, or mixed fibers

- Consolidation Options: Needle punching or resin bonding

Why Airlay Non-Wovens?

The Airlay process allows for randomized fiber orientation using controlled airflows, producing flexible, breathable, and highly consistent felts used across various industries, from automotive to construction and filtration.

Problem: Growing demand for sustainable, uniform, and customizable felts for industrial applications.

Solution: Margasa’s Airlay lines use aerodynamic fiber placement and scalable consolidation methods (needling or thermal) to deliver consistent results with high throughput and material flexibility.

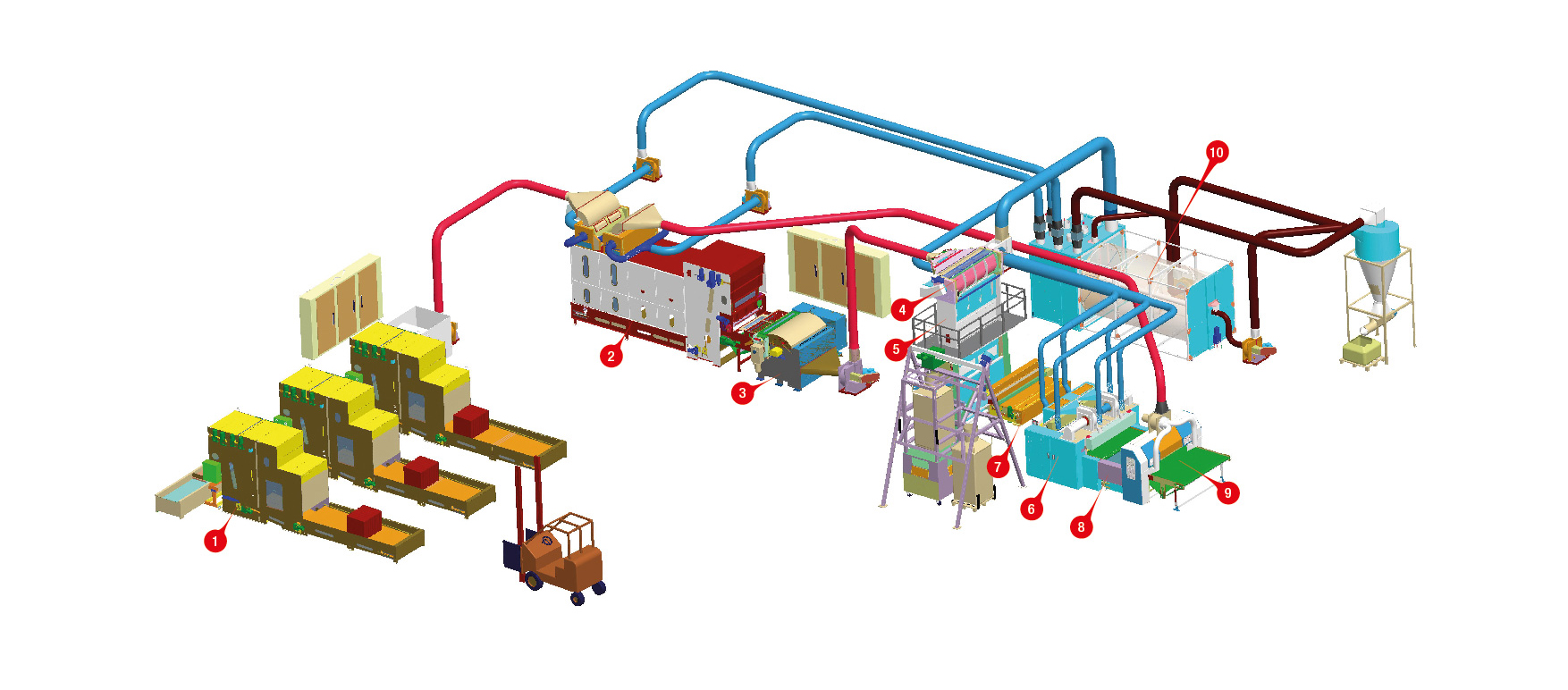

Line Structure

Our Airlay lines are composed of modular machines grouped by key production phases. Each module is optimized for material preparation, web forming, and fiber consolidation:

Fiber Preparation and Blending

- APC-1500 Continuous Openers

- AB-AMU 1500/2000 bale opener with integrated fine opener

- ABC Silo + MCM Fine Opener

Web Forming: Airlay Technology

Consolidation Systems (Mechanical or Thermal)

- Fixes fibers together to form stable, usable non-woven fabric

- Needle punching or thermobonding ovens (chemical consolidation)

End of Line

Filtration and Pneumatic Transport

- Air quality management and material movement between phases.

- Rotary Filter

- Pneumatic transport

- All

- Web forming

- Fibre preparation and combination